In any industrial setup, maintaining proper airflow and temperature control is non-negotiable. Whether it’s for exhausting fumes, ventilating workspaces, or channeling heated air, the efficiency of your ventilation system can directly impact both worker safety and equipment longevity. Among the critical components in these systems, flexible expansion alloy ducts have emerged as a preferred solution for modern industries—and for good reason.

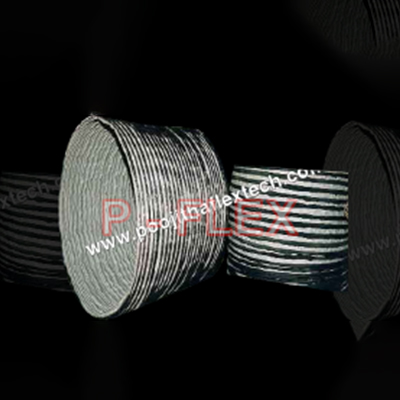

Flexible expansion alloy ducts are specialized ducting systems designed to transport air, gases, or fumes across industrial units. Built from durable alloy materials and engineered for flexibility, they serve as a vital connection between two static points in a ventilation or piping system. These ducts can expand, bend, and contract based on operational demands, making them far more adaptable than rigid counterparts.

1. Excellent Flexibility and Vibration Absorption

One of the standout features of these ducts is their ability to accommodate movement. Whether it’s equipment vibrations or shifts caused by operational dynamics, these ducts absorb motion without damage. Their flexibility also simplifies installation in tight corners or irregular layouts, reducing the need for multiple joints or bends.

2. Adaptability to Temperature Changes

In environments where equipment or gases reach extreme temperatures, traditional ducts can become brittle or warped. Flexible expansion alloy ducts are engineered to handle thermal fluctuations effortlessly. They expand and contract as needed without compromising structural integrity, making them ideal for both hot and cold air movement.

3. Resistance to Corrosive Environments

Industries dealing with harsh chemicals or exposure to moisture require ducting that doesn’t degrade quickly. These ducts are corrosion-resistant, offering long-term durability in aggressive environments such as chemical processing, metal refining, or even food manufacturing, where hygiene and longevity are crucial.

4. Reduced Maintenance and Operational Downtime

Because of their robust design and fewer mechanical joints, these ducts typically require less frequent maintenance. Their resistance to wear and tear minimizes unplanned downtimes and ensures continuous system performance. This is a major cost-saver for large-scale industrial operations.

View Products

View Products

View Products

View Products

The versatility of flexible expansion alloy ducts makes them a reliable choice across various industrial sectors:

Choosing the correct ducting depends on several operational factors:

Working with a trusted manufacturer or supplier can help in customizing the duct to your exact specifications and ensure optimal performance.

When it comes to quality and innovation in ducting solutions, Poojitha Flex Technologies has set a benchmark in the industry. With a focus on precision engineering, material strength, and customer-specific customization, the company provides flexible expansion alloy ducts that meet the diverse needs of modern industry. Their commitment to reliability and customer support makes them a preferred partner for businesses nationwide.

Flexible expansion alloy ducts are not just components—they’re critical elements that ensure your industrial ventilation systems operate efficiently, safely, and cost-effectively.

1. What are flexible expansion alloy ducts used for in industrial systems?

Flexible expansion alloy ducts are used to transport air, gases, and fumes in industrial ventilation systems. They accommodate movement, absorb vibrations, and adjust to temperature changes, making them ideal for dynamic environments.

2. How are flexible alloy ducts different from rigid ducts?

Unlike rigid ducts, flexible alloy ducts can bend, stretch, and compress without breaking. This makes them easier to install in confined spaces and more capable of handling vibrations and thermal expansion.

3. Are flexible expansion alloy ducts heat resistant?

Yes, these ducts are specifically designed to withstand high-temperature environments. They expand and contract safely with changing heat levels, making them suitable for systems carrying hot air or gases.

4. Can these ducts be used in chemical or corrosive environments?

Absolutely. The alloy material offers excellent corrosion resistance, making these ducts suitable for industries like chemical processing, pharmaceuticals, and metal refining.

5. What sizes are available for flexible expansion ducts?

These ducts are available in a range of diameters and lengths, and many manufacturers offer customization to match your specific system requirements.

6. How do flexible ducts reduce maintenance costs?

Thanks to their durability and resistance to wear, they require less frequent repairs or replacements. Their ability to absorb mechanical stress also protects connected systems, reducing downtime.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.