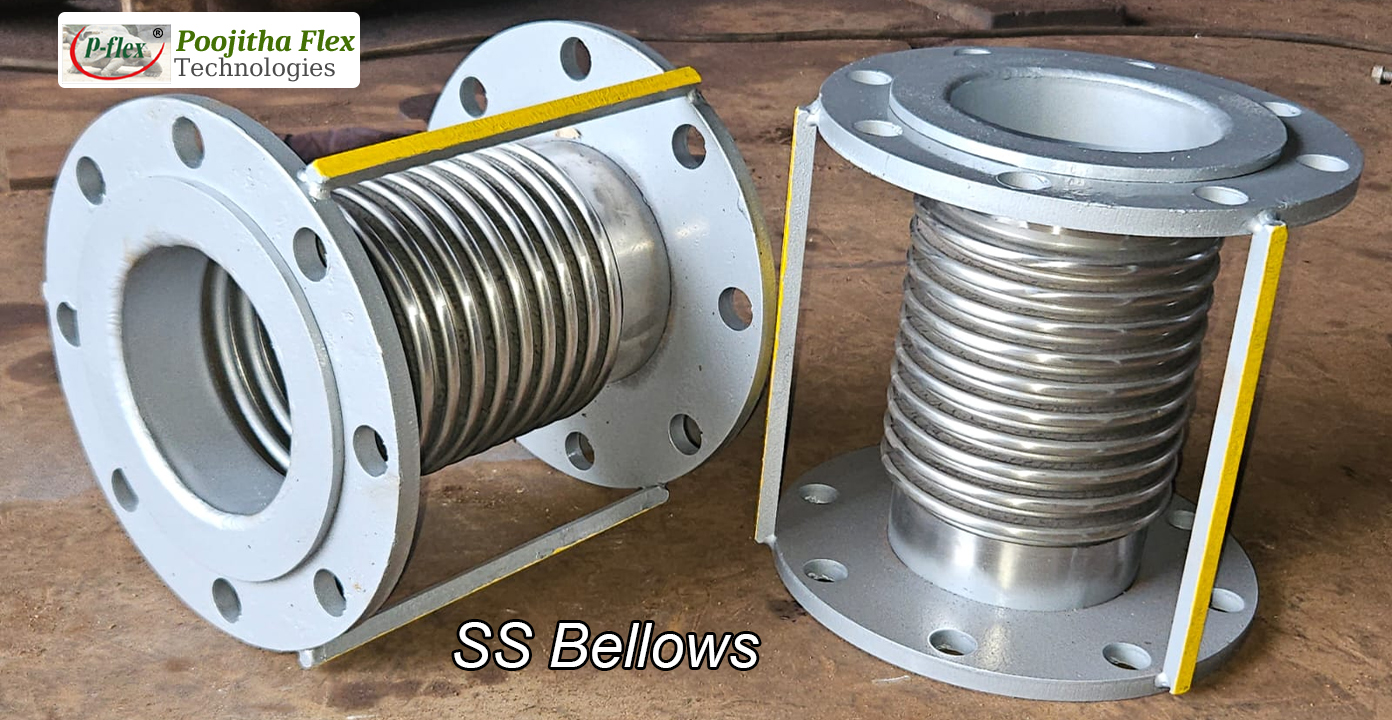

In modern industrial applications, protecting machine components from dust, debris, and mechanical wear is crucial. Ss Laminate Bellows serve as highly durable, flexible protective covers designed for demanding environments. Poojitha Flex Technologies, operating as a reliable Manufacturer and Exporter, specializes in these solutions along with Rubber Expansion Bellows, Black Bellow Pads, and Telescopic Covers.

These bellows not only shield precision machinery like Laser Cutting Machines but also extend the operational life of components by absorbing vibrations, thermal expansions, and mechanical shocks. Their adaptability across industries such as metalworking, robotics, and automation makes them a preferred choice among engineers.

A high-quality Ss Laminate Bellow combines flexibility with structural strength. Typically, these bellows are made of stainless steel laminates arranged to provide smooth expansion and contraction cycles. Key design principles include:

By adhering to these principles, Poojitha Flex Technologies ensures that every bellow maintains shape and resilience even in high-speed operations.

View Products

View Products

View Products

View Products

The selection of stainless steel laminates is critical for both performance and longevity. Key material considerations include:

Ss Laminate Bellows outperform traditional rubber or fabric alternatives in industrial environments where abrasion resistance and high mechanical load capacity are required.

Ss Laminate Bellows are versatile and widely used. Some common applications include:

These bellows ensure equipment runs smoothly while minimizing downtime due to component wear or contamination.

Engineers must consider multiple factors when specifying bellows:

Poojitha Flex Technologies provides tailored solutions to meet these criteria, ensuring compatibility with client machinery and operational requirements.

The advantages of investing in high-quality Ss Laminate Bellows include:

These benefits make laminate bellows the preferred choice for industrial automation and precision machinery.

The manufacturing of Ss Laminate Bellows involves several technical steps:

The process ensures every bellow can withstand repeated cycles of expansion and contraction without structural failure.

Even high-quality bellows benefit from regular maintenance:

Proper maintenance enhances operational reliability and minimizes production interruptions.

Here is a concise technical snapshot for engineers and procurement teams:

Ss Laminate Bellows are inherently safe, but proper usage ensures optimal performance:

Following these guidelines reduces the likelihood of mechanical failure and ensures reliable machine protection.

Poojitha Flex Technologies is a leading Manufacturer and Exporter specializing in Ss Laminate Bellows, Rubber Expansion Bellows, Telescopic Covers, and other flexible protective solutions. Their focus on precision engineering, material quality, and rigorous testing makes them a trusted partner for industries requiring reliable machine protection. With custom design capabilities, Poojitha Flex Technologies delivers solutions tailored to client machinery and industrial requirements worldwide.

1. What are Ss Laminate Bellows used for?

They protect moving machine parts, prevent contamination, and absorb vibrations in industrial equipment like laser cutting machines and telescopic covers.

2. How long do these bellows last?

With proper installation and maintenance, Ss Laminate Bellows can last millions of expansion/contraction cycles over several years.

3. Can they handle high temperatures?

Yes, depending on material grade, these bellows typically withstand -20 to 400 degree Celsius.

4. Are they customizable?

Yes, Poojitha Flex Technologies offers custom sizes, thickness, and mounting options tailored to client machinery.

5. How do they compare to rubber bellows?

Ss Laminate Bellows offer superior wear resistance, higher temperature tolerance, and longer life compared to rubber alternatives.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.