Industrial machines, particularly CNC, hydraulic, and precision equipment, are exposed to dust, debris, and harsh operating conditions. Telescopic covers are engineered solutions that protect moving machine components, extend equipment life, and ensure consistent performance.

Poojitha Flex Technologies, a renowned Manufacturer and Exporter, specializes in high-quality telescopic covers designed for durability, precision, and operational efficiency. By integrating advanced materials and engineering, these covers provide superior protection and performance across various industrial sectors.

Telescopic covers are expandable protective covers that slide over machine components, such as guideways, screws, and rods, to prevent contamination from dust, chips, coolant, or other foreign particles.

Key functions

Unlike standard static covers, telescopic designs allow for flexible expansion and contraction, adapting to the machine’s motion while maintaining consistent protection.

View Products

View Products

View Products

View Products

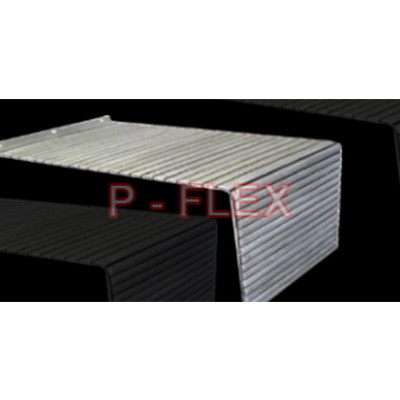

The performance of telescopic covers heavily depends on material selection and construction techniques.

Common materials include:

Engineering plastics: High wear resistance and chemical stability for specialized applications.

Construction techniques:

Poojitha Flex Technologies ensures precision fabrication, tight tolerances, and reinforced segments for long-lasting durability.

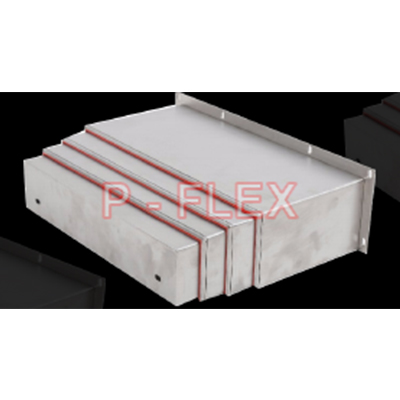

1. Machine Component Protection

Telescopic covers shield guideways, linear rails, ball screws, and rods from chips, dust, and coolant. This reduces wear, improves precision, and prevents component failure.

2. Extended Equipment Lifespan

By protecting sensitive components from contaminants, telescopic covers minimize maintenance frequency and extend machine life, reducing operational costs.

3. Enhanced Operational Efficiency

Smooth, protected movements maintain accuracy and repeatability, ensuring machines operate at peak performance with minimal downtime.

4. Safety Enhancement

Covers reduce exposure to moving parts, safeguarding operators from accidental injuries and meeting workplace safety standards.

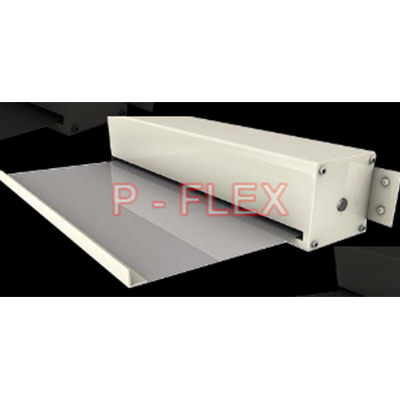

5. Adaptability Across Applications

Telescopic covers can be customized for CNC machines, hydraulic presses, lathes, milling machines, and robotic systems, adapting to different sizes, movements, and environmental conditions.

6. Reduced Maintenance and Cleaning Effort

Protecting components from dust and debris lowers the frequency of cleaning and lubrication, saving time and labor costs.

7. Cost-Effective Solution

By preventing premature component failure, telescopic covers reduce repair and replacement costs, offering long-term financial benefits for industries.

Poojitha Flex Technologies offers customizable telescopic covers to meet specific industrial requirements:

Customization ensures that every cover fits perfectly, maximizes protection, and maintains machine performance.

Telescopic covers are widely used across multiple industries:

These covers are essential in any sector where precision, durability, and protection are critical to operational efficiency.

Proper maintenance enhances performance and lifespan:

Following these practices ensures consistent protection and minimal downtime.

Poojitha Flex Technologies stands out as a Manufacturer and Exporter of industrial telescopic covers due to:

By choosing Poojitha Flex Technologies, industries gain durable, efficient, and highly reliable telescopic covers designed to enhance machine performance and reduce maintenance costs.

Q1: What is the primary purpose of telescopic covers in machinery?

A: They protect moving components like guideways, ball screws, and rods from dust, debris, coolant, and mechanical wear, ensuring smooth operation.

Q2: Which materials are commonly used for industrial telescopic covers?

A: Cold-rolled steel, stainless steel, aluminum alloys, and engineering plastics are selected based on strength, durability, and environmental resistance.

Q3: Can telescopic covers be customized?

A: Yes, they can be tailored in dimensions, segment count, materials, and stroke lengths to match specific machine requirements.

Q4: How do telescopic covers enhance machine lifespan?

A: By preventing abrasion, corrosion, and contamination, telescopic covers reduce wear on components, ensuring longer operational life.

Q5: Which machines benefit most from telescopic covers?

A: CNC machines, hydraulic presses, linear systems, robotic axes, and metalworking machinery benefit from protection and performance optimization.

Q6: How should telescopic covers be maintained?

A: Regular inspection, cleaning, lubrication of joints, proper alignment, and storage in suitable conditions ensure optimal performance and longevity.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.