Manufacturing machines face harsh operating conditions where dust, swarf, lubrication splashes, and thermal variation constantly challenge durability. This is exactly where link apron covers designed by Poojitha Flex Technologies stand apart, delivering structured protection, mechanical stability, and longevity. As a trusted Manufacturer and Exporter, the company builds solutions that support industries depending on uninterrupted machine motion, accurate guiding surfaces, and trouble-free automation cycles.

The journey of link apron covers is a story of materials, mechanics, and manufacturing discipline. Their purpose appears simple at first glance, yet behind this product lies a layered engineering philosophy that blends structural integrity, motion flexibility, and contamination control.

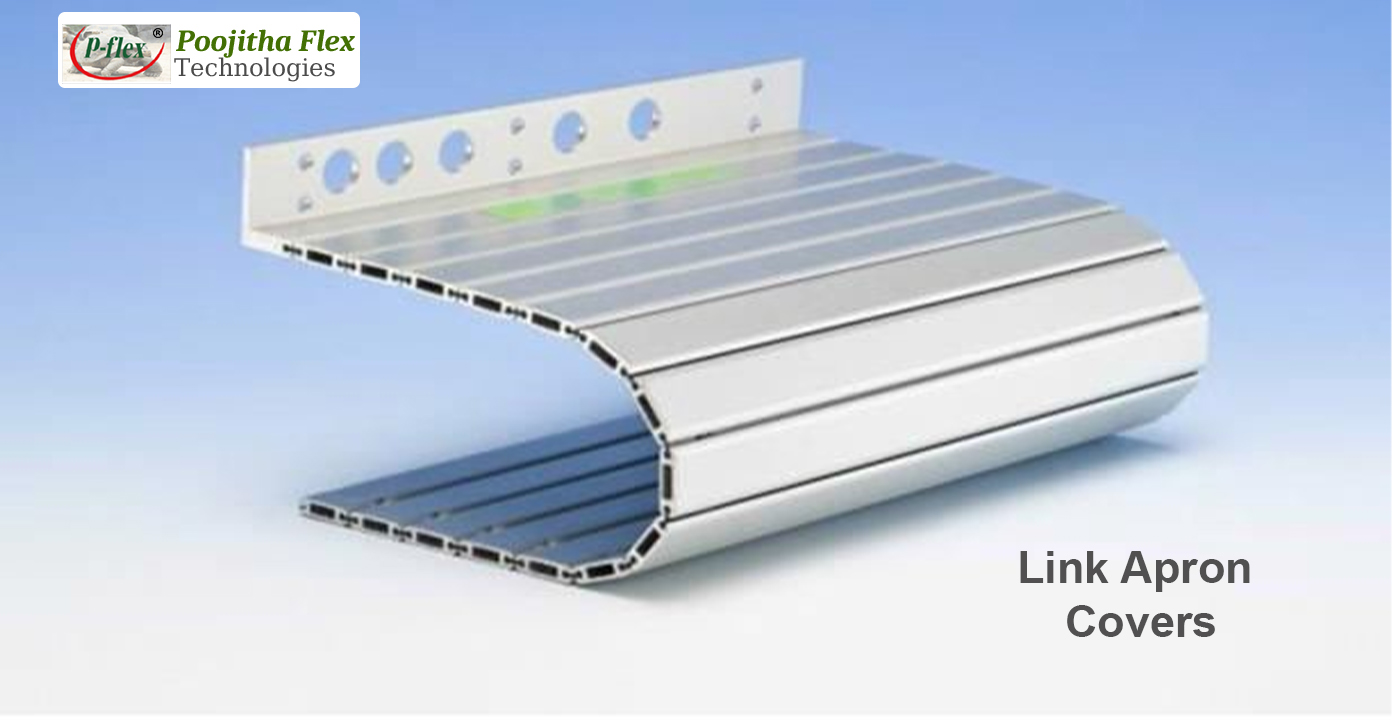

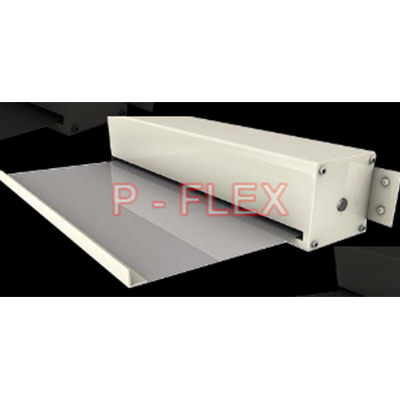

Link apron covers bring together a chain-like series of metal or composite links that offer exceptional resistance to abrasion while allowing smooth bending along machine axes. When examining these covers, one quickly understands why industries dealing with CNC cutting, metal forming, robotics, and automated conveyors rely on link apron covers to safeguard their machinery.

The mechanical purpose is straightforward:

Protect machine ways, guide rails, and moving assemblies from contamination.

But the engineering behind this protection is deeply structured.

Every high performance apron cover begins with a material decision. Stainless steel link apron covers and steel apron covers are popular for their exceptional rigidity, while aluminum or composite versions help reduce inertia in rapid-motion systems.

The raw material determines:

This is why industries using corrosive fluids or high heat zones prefer stainless steel link aprons, while high speed CNC machines may opt for lightweight mechanical link designs.

View Products

View Products

View Products

View Products

The defining characteristic of link apron covers is their segmented design. Each link interlocks mechanically, creating a protective surface that can articulate smoothly without tearing or wrinkling like fabric-based bellows.

This mechanical rhythm of movement makes mechanical link covers reliable for vertical, horizontal, and inverted installations.

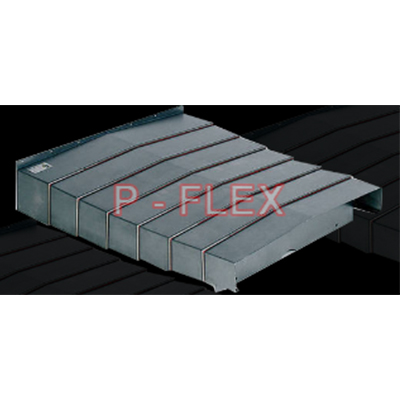

The performance of a link apron cover often depends on its hinge geometry. The hinges are not only connectors; they are precision elements engineered to control bending radius and travel orientation.

One of the strongest technical advantages of CNC apron covers lies in how the hinge assembly distributes friction uniformly across the links. This prevents the dragging effect that can damage guide rails over time.

Some hinge systems are reinforced with bushings or treated pins, enhancing endurance in high cycle environments like laser cutting machines and robotic actuators.

Industrial environments generate an enormous amount of particulate and liquid contaminants. Metal chips, coolant spray, dust, and carbon residue can ruin precision surfaces if not properly controlled.

This is where machine way protection using link apron designs becomes essential. Their interlocked metallic surface forms a strong barrier that shields moving assemblies from degradation.

The rigid metallic shield does not collapse or tear like rubber or textile covers. This makes industrial apron shields ideal for factories that work with abrasive manufacturing processes.

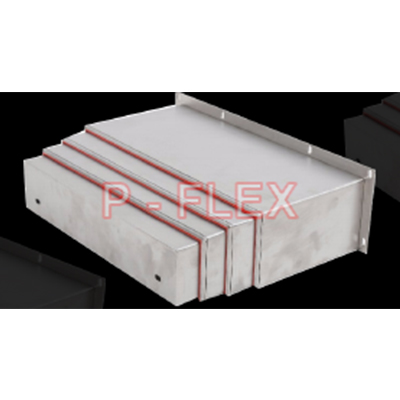

The construction of metal apron covers involves deeply controlled fabrication techniques. Every link must be machined to precise thickness, curvature, and alignment.

Poojitha Flex Technologies pays special attention to repeat accuracy in the hinge assembly. As a dedicated Manufacturer and Exporter, the company ensures that every apron cover meets consistent mechanical performance standards.

These covers are used wherever surfaces need robust, durable, rigid protection without sacrificing movement flexibility.

Their ability to withstand heat, abrasion, and mechanical load makes link apron covers one of the most dependable machine protection solutions.

Poojitha Flex Technologies stands as a distinguished Manufacturer and Exporter of machine protection systems, offering a wide variety of products such as link apron covers, rubber expansion bellows, laser cutting bellows, SS laminate bellows, telescopic covers, and other precision protective components.

With a deep understanding of machine safeguarding requirements, the company ensures durability, precision, and long term dependability across every product.

1. What are link apron covers used for?

They protect machine guideways, linear movement assemblies, and exposed surfaces from chips, coolant, dust, and abrasive particles.

2. Are link apron covers suitable for high temperature environments?

Yes. Stainless steel or alloy versions can withstand elevated temperatures, making them ideal for machining and laser cutting operations.

3. Can link apron covers be customized?

Yes. Width, thickness, hinge type, radius, material, finish, and mounting style can all be customized to fit machine requirements.

4. How do they differ from textile bellows?

Link aprons are rigid, more durable, heat resistant, and provide superior protection against sharp debris compared to fabric bellows.

5. Does Poojitha Flex Technologies provide installation support?

Yes, as a leading Manufacturer and Exporter, the company assists with sizing, mounting guidance, and application specific support.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.