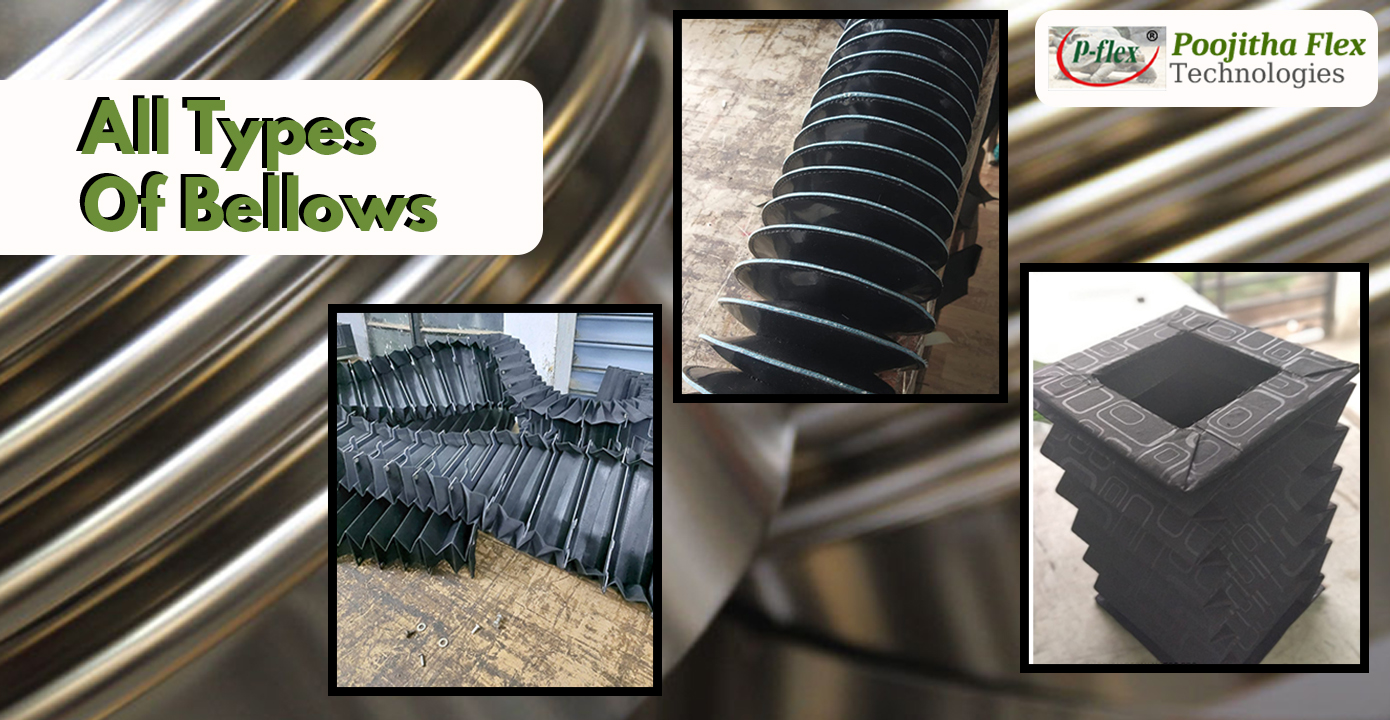

Bellows are one of the most essential components in industrial machinery, designed to protect moving parts, absorb vibration, and ensure operational efficiency. Whether it is for dust protection, expansion, or sealing, bellows play a critical role in maintaining the longevity and reliability of equipment.

Poojitha Flex Technologies, established in 1980, has built a strong reputation as a manufacturer, exporter, and wholesale supplier of high-quality bellows in India and global markets. With over four decades of experience, the company has been catering to diverse industrial applications with precision-engineered products at economical prices.

The company specializes in:

With expertise in advanced manufacturing techniques and customer-focused design, Poojitha Flex Technologies ensures durable, cost-effective, and application-specific solutions.

View Products

View Products

View Products

View Products

Below is a detailed table presenting different types of bellows with their specifications, applications, and benefits:

| Type of Bellow | Material | Applications | Temperature Range | Pressure Capacity | Durability / Life Cycle | Customization Options | Key Features |

|---|---|---|---|---|---|---|---|

| Black Bellow Pad | Rubber / Synthetic Elastomers | CNC machines, hydraulic presses, machinery covers | -20°C to +80°C | Up to 5 bar | 1–2 years (heavy use) | Multiple shapes & thicknesses | Heat resistant, dust protection, economical |

| Rubber Expansion Bellows | Natural Rubber, EPDM, Neoprene | Pipelines, HVAC systems, water treatment plants | -30°C to +120°C | 10–16 bar | 5–10 years | Sizes, flanges, lining available | Absorbs vibration, compensates thermal expansion |

| Laser Cutting Machine Bellows | PU coated / Fire-retardant fabric | Laser cutting & engraving machines | -10°C to +100°C | Low pressure (<2 bar) | High durability against sparks & dust | Shape & coating customization | High wear resistance, spark proof |

| Telescopic Cover Bellows | Stainless Steel, PU-coated fabric | Guideways of machine tools | -40°C to +250°C | Mechanical loads (not fluid pressure) | 10+ years | Custom dimensions, fold types | Heavy-duty protection, high-speed use |

| SS Laminate Bellows | Stainless Steel + Laminate Composite | Medical, defense, automation | -60°C to +400°C | Up to 25 bar | 15+ years | Designs for harsh environments | Corrosion & chemical resistant |

| Fabric Bellows | Nylon, Canvas, PU, PVC-coated fabrics | Air ducts, blowers, compressors | -20°C to +150°C | Low pressure (<1.5 bar) | 3–6 years | Round, square, flexible designs | Lightweight, corrosion resistant |

| Metallic Bellows | Stainless Steel, Inconel, Brass | Pipelines, exhaust systems, aerospace | -200°C to +700°C | Up to 50 bar | 20+ years | Axial, lateral, angular designs | Handles extreme conditions |

| Square / Rectangular Bellows | Rubber, Fabric, or Metal | Special-purpose machines, lifting equipment | -20°C to +150°C | 2–15 bar (depending on material) | 3–10 years | Tailored to equipment size | Reliable sealing, non-round equipment |

| PU Bellows | Polyurethane | Packaging machines, automotive parts | -30°C to +120°C | Up to 5 bar | 5–7 years | Custom thickness & colors | Elastic, abrasion resistant |

Choosing the right bellows requires technical understanding. Here are key factors to consider:

Bellows are the backbone of machinery protection and performance. Whether it’s rubber expansion bellows for pipelines, telescopic covers for CNC machines, or stainless steel laminate bellows for medical equipment, the right choice ensures longer life, higher efficiency, and reduced maintenance costs.

With a legacy since 1980, Poojitha Flex Technologies is among the most reliable manufacturers and exporters of all types of bellows. Offering durability, precision, and cost-effectiveness, the company continues to serve industries in India and abroad with unmatched quality.

If you are looking for the best bellows manufacturer and exporter at an economical price, Poojitha Flex Technologies is your trusted partner.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.