Bellows play a critical role in protecting machine components from external contaminants while allowing smooth and controlled movement. In modern machinery, where precision and safety are essential, bellows act as a protective barrier against dust, metal chips, coolant splashes, oil, and debris that can damage sensitive parts such as guideways, spindles, and screws.

By preventing contamination and mechanical wear, bellows significantly extend equipment life, reduce downtime, and enhance operator safety. With increasing automation and complex machine movements across industries, the demand for customized, application-specific bellows has grown rapidly. Poojitha Flex Technologies stands out as a trusted bellows manufacturer, offering high-quality, engineered solutions tailored to diverse industrial requirements.

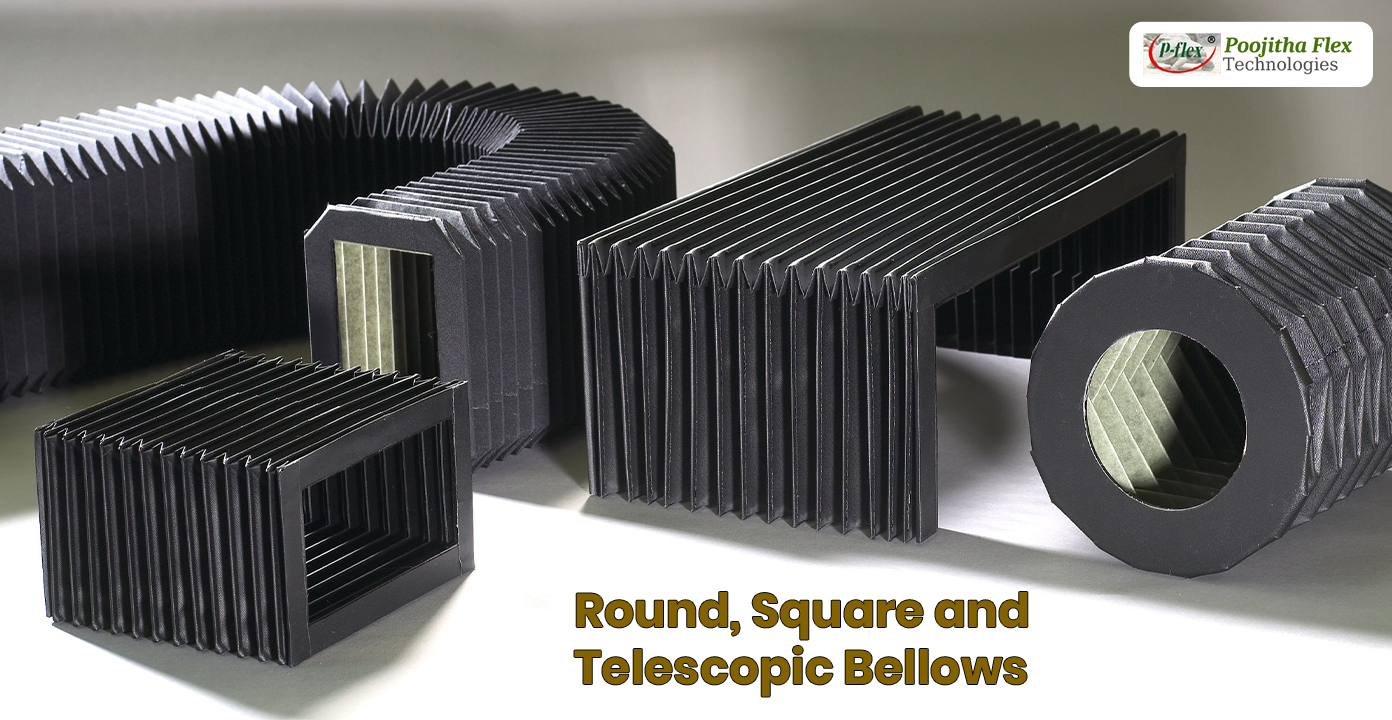

Machine bellows are flexible protective covers designed to shield moving machine parts from environmental and operational hazards. They expand and compress in sync with machine motion while maintaining a sealed protective enclosure.

Bellows protect machines from dust, metal chips, coolant, oil splashes, and abrasive particles that can affect accuracy and performance. Depending on the application, bellows can support linear, rotary, angular, or combined movements. Common materials used include coated fabrics, rubberized textiles, PVC, polyurethane, and special composites selected based on temperature, chemical exposure, and mechanical stress.

Round bellows are cylindrical protective covers designed primarily for machines with circular or axial movement. Their symmetrical shape allows uniform expansion and compression, making them ideal for applications involving spindles, shafts, and rotary mechanisms. These bellows are widely used in CNC machines, drilling machines, and automation systems where smooth motion and compact protection are required.

Advantages and Limitations:

Round bellows offer smooth movement and easy installation but provide limited coverage for wide or complex machine geometries.

Square bellows are designed to protect machine components with rectangular or flat movement paths. Their box-like structure provides wider coverage, making them suitable for machine beds, guideways, and sliding tables. These bellows are commonly used in milling machines, machining centers, and industrial automation equipment.

View Products

View Products

View Products

Advantages and Limitations:

Square bellows offer excellent protection and coverage but require precise customization to ensure smooth folding and long service life.

Telescopic covers are multi-stage protective systems designed for machines with long travel distances and heavy-duty operating conditions. Their sliding structure allows multiple sections to collapse and extend smoothly, offering robust protection even under high mechanical stress. These bellows are commonly used in heavy machinery, large CNC machines, and industrial equipment with extended strokes.

Advantages and Limitations:

Telescopic covers provide superior protection and durability but are more complex in design and require accurate installation and alignment.

| Aspect | Round Bellows | Square Bellows | Telescopic Covers |

|---|---|---|---|

| Shape & Movement Compatibility | Cylindrical geometry supports axial, radial, and rotary movements, making it ideal for spindles and shafts. | Rectangular geometry matches linear guideways and flat machine beds with straight-line motion. | Multi-stage sliding structure supports long linear strokes with controlled extension and retraction. |

| Stroke Length Capability | Suitable for short to medium stroke lengths with smooth expansion and compression. | Handles medium stroke lengths efficiently with consistent folding behavior. | Designed for very long stroke lengths where compact retraction is critical. |

| Level of Protection Offered | Protects against dust, fine chips, oil mist, and light coolant exposure. | Provides enhanced coverage against metal chips, coolant splash, and abrasive debris. | Offers maximum protection against heavy chips, high-pressure coolant, heat, and harsh contaminants. |

| Load-Bearing Capability | Limited load resistance; primarily protective rather than structural. | Moderate resistance to external pressure and chip impact. | High resistance to mechanical impact, falling chips, and aggressive industrial conditions. |

| Performance Under Continuous Operation | Performs reliably in moderate-duty cycles with repetitive motion. | Well-suited for continuous linear operation in production environments. | Optimized for heavy-duty, high-cycle, and long-duration industrial operations. |

| Space Utilization Efficiency | Highly space-efficient; ideal for compact machine designs. | Requires moderate space to accommodate folds and mounting frames. | Requires more installation space but offers excellent retraction efficiency relative to stroke length. |

| Installation & Alignment Sensitivity | Simple installation with minimal alignment requirements. | Requires accurate mounting to prevent uneven folding and wear. | Demands precise alignment to ensure smooth telescoping and avoid jamming. |

| Customization Flexibility | Easily customizable in diameter, length, and material thickness. | Highly customizable in width, height, and fold depth. | Custom-built based on stroke length, load, and environmental severity. |

| Material Thickness & Reinforcement | Generally lighter materials to maintain flexibility. | Medium-thickness materials with optional internal supports. | Uses thicker materials, internal frames, or metal lamellas for reinforcement. |

| Maintenance & Inspection Needs | Low maintenance with basic periodic inspection. | Moderate maintenance to check fold integrity and mounting points. | Requires scheduled inspection due to complex structure and heavy-duty usage. |

| Cost Consideration | Cost-effective solution for standard protection needs. | Mid-range cost depending on size and customization. | Higher initial cost justified by durability and extreme performance capability. |

| Typical Use Case Priority | Precision movement, compact machines, rotary parts. | Linear guide protection, machine beds, and slides. | Heavy-duty machines, long travel axes, and harsh industrial environments. |

View Products

View Products

View Products

Selecting the right bellows starts with understanding the machine’s movement pattern, stroke length, and working environment. Linear, rotary, or combined movements require different bellows designs such as round, square, or telescopic types. The available installation space, mounting method, and exposure to contaminants like chips, coolant, oil, or heat play a critical role in determining the correct bellows configuration. A well-matched design ensures effective protection without restricting machine motion.

Performance expectations vary based on duty cycle, operating speed, and environmental severity. Machines running in continuous or heavy-duty operations demand bellows with reinforced materials, higher fold endurance, and resistance to abrasion and temperature fluctuations. Choosing bellows designed for the required motion life and load conditions helps minimize wear, reduce downtime, and extend service life in demanding industrial applications.

While initial cost is an important factor, long-term value should be the primary consideration. Low-cost bellows may require frequent replacements, increasing maintenance expenses and machine downtime. High-quality bellows, though slightly higher in upfront cost, offer better durability, consistent performance, and lower lifecycle costs. Investing in the right bellows ensures uninterrupted machine operation and long-term savings.

With extensive experience in designing and manufacturing customized bellows, Poojitha Flex Technologies provides expert technical guidance throughout the selection process. From evaluating machine drawings to recommending suitable materials and designs, their team ensures each bellows solution is optimized for performance, durability, and application-specific requirements.

Poojitha Flex Technologies is a trusted name in the design and manufacture of high-quality machine bellows, offering reliable solutions tailored to diverse industrial needs. Their ability to deliver customized round, square, and telescopic bellows ensures precise fit, optimal protection, and superior performance across applications.

With deep industry expertise and strong technical support, the company works closely with customers to understand machine requirements and operating conditions. This customer-centric approach results in bellows solutions that enhance machine life, improve operational safety, and reduce maintenance costs.

Backed by reliable production capabilities, timely delivery, and dependable after-sales service, Poojitha Flex Technologies stands out as a long-term partner for industries seeking durable, efficient, and high-performance bellows solutions.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.