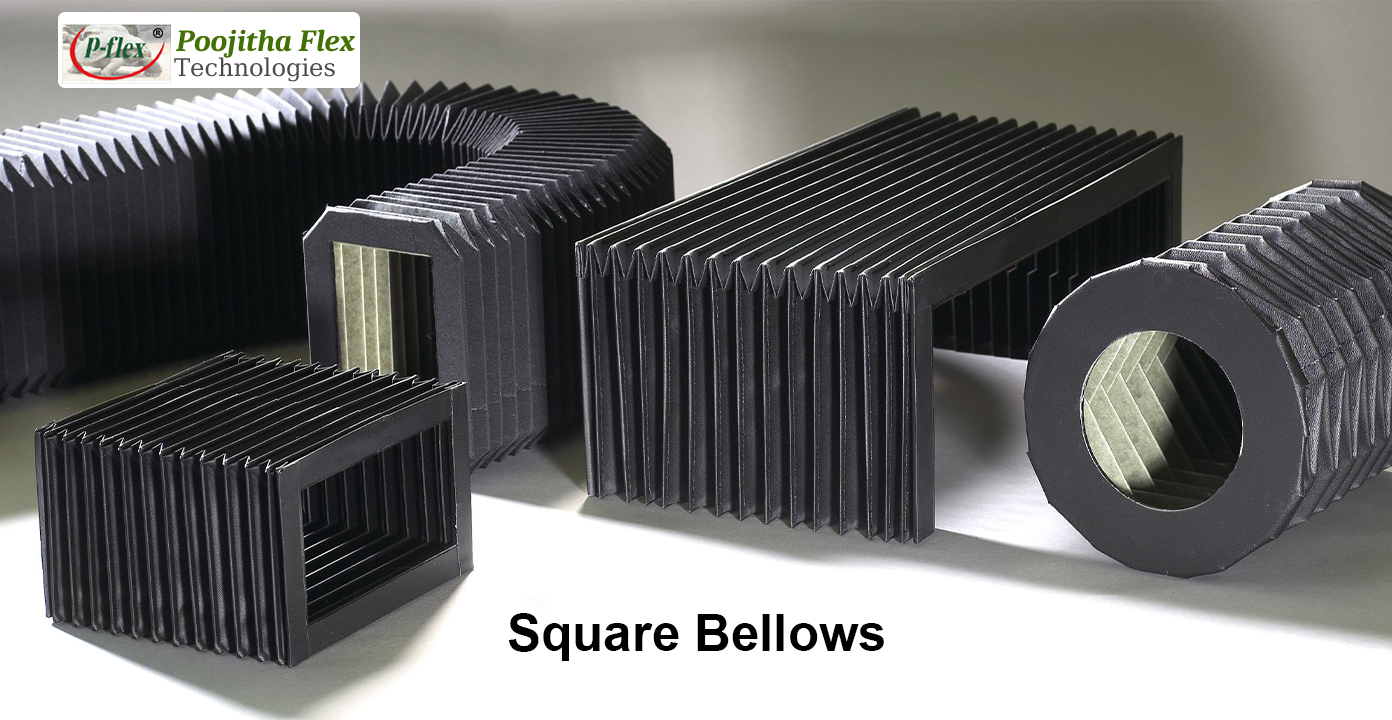

When industries rely on accuracy, repeatability, and motion stability, they depend on small components that carry enormous responsibility. Among them, Square Bellows quietly serve as the protective spine for machines designed to move with speed and precision. In modern CNC lines, cutting centers, laser machines, telescopic systems, and heavy industrial equipment, the presence of a strong, flexible, and contamination-resistant bellow can decide how long the machinery survives. This is where Poojitha Flex Technologies, a trusted Manufacturer and Exporter, introduces a new standard of engineered shielding for advanced industrial environments.

Engineers needed a protective component that could move along with the machine, expand and collapse smoothly, endure extreme temperatures, and remain unaffected by metal or chemical exposure. Square bellows emerged as the answer and gradually transformed into a core protective component across industries.

Today, Square Bellows are essential wherever accuracy and equipment lifespan matter. They function as flexible shields that block contaminants, stabilize motion paths, and maintain clean machine interiors so operations remain uninterrupted.

View Products

View Products

View Products

View Products

As industries move toward precision based and automation driven production, even a small error caused by dust or debris can result in machine downtime. This is where square bellows redefine operational reliability.

They provide:

These bellows are built using high grade polyurethane coated fabrics, synthetic polymers, laminated materials, heat resistant cloth, and custom stitched structural ribs. Each part is selected depending on humidity, temperature, machine environment, and the type of exposure expected.

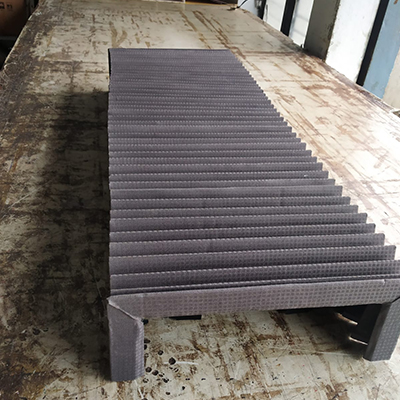

To understand how they work, picture a multi folded structure designed to expand and shrink with motion. Every fold distributes stress, absorbs vibration, and creates a uniform shield around moving assembly lines. The geometry of the square shape adds stability, especially when protecting linear mechanisms that move along rails or box sections.

The materials used in these bellows are chosen for strength, elasticity, and resistance. Their folded construction ensures smooth operation, even during fast movement cycles. They are sealed carefully so air, heat, chemicals, dust, or metal chips cannot reach the machine components inside.

Below is a clean and readable technical specification style section, written in bullet points exactly as you prefer for technical clarity:

Square bellows are selected across industries where protection and precision are vital. Their ability to handle harsh environments makes them the preferred choice for:

Imagine a laser cutting unit working nonstop for eight hours. Every second, sparks and molten particles shoot downward. If the machine’s linear guides were exposed, the damage would be immediate. But laser cutting bellows remain expanded, absorbing heat, shielding components, and making sure the operator does not worry about contamination.

Or imagine a CNC milling center pushing through dense metal. Micro dust generated from cutting tries to settle on machine components. Yet square bellows aligned with the telescopic cover block every particle so the cutting head maintains accuracy and consistency.

Across industrial floors, thousands of machines continue delivering performance because their most sensitive components remain guarded by these protective bellows.

As a Manufacturer and Exporter, Poojitha Flex Technologies offers customization, robust material engineering, and precision stitched bellows that match global standards. Their production team uses advanced machinery, skilled craftsmanship, and quality control systems that ensure every bellow performs consistently under industrial loads.

Their bellows integrate seamlessly with the customer’s existing machinery, maintaining the harmony between protection and motion. This is why industries across CNC machining, metal processing, packaging, automation, and robotics rely on them.

Poojitha Flex Technologies has positioned itself as a trusted Manufacturer and Exporter of high performance industrial bellows, protective covers, and machine guarding systems. Their focus on quality engineering, advanced fabrication, and customization makes them a preferred supplier for industries seeking precision, durability, and long term reliability.

1. What materials are Square Bellows made from?

They are typically made from polymer coated fabric, synthetic rubberized cloth, laminated materials, or heat resistant textiles depending on machine requirements.

2. Where are Square Bellows used?

They are widely used in CNC machines, telescopic covers, laser cutting systems, automation lines, and heavy industrial machinery.

3. Can Square Bellows handle high temperature environments?

Yes, high temperature resistant fabrics can be selected depending on the machine environment.

4. Are custom sizes available?

Yes, Square Bellows can be fully customized in size, stroke length, and material based on your machine.

5. How long do Square Bellows last?

Lifespan depends on usage conditions, material selection, and load cycling, but high quality bellows typically offer long operational life with minimal maintenance.

Copyright © 2026 Poojitha Flex Technologies All Rights Reserved.